With over almost 20 years. Of business in both our domestic market and overseas market, they are the word’s largest fast moving Bakery and Biscuit companies. With more than 15 products offering in the market, the Company is a part of the everyday life of millions of consumers across the world. Proud to get associated with a great brand ZILI that has created a positive social impact.

In Bakery Industries, hygiene is paramount and demands frequent cleaning of the equipment involved. Our customer’s challenge was no different. Frequent disengagement of the rotary valve to remove and then clean it was a challenge. Maintenance time used to be as high as 1.5 hrs. to 2 hrs. Frequent engagement and disengagement of the rotary valve resulted in the shorter life of the shaft’s seals, thereby, need to regularly replace the rotary valve itself.

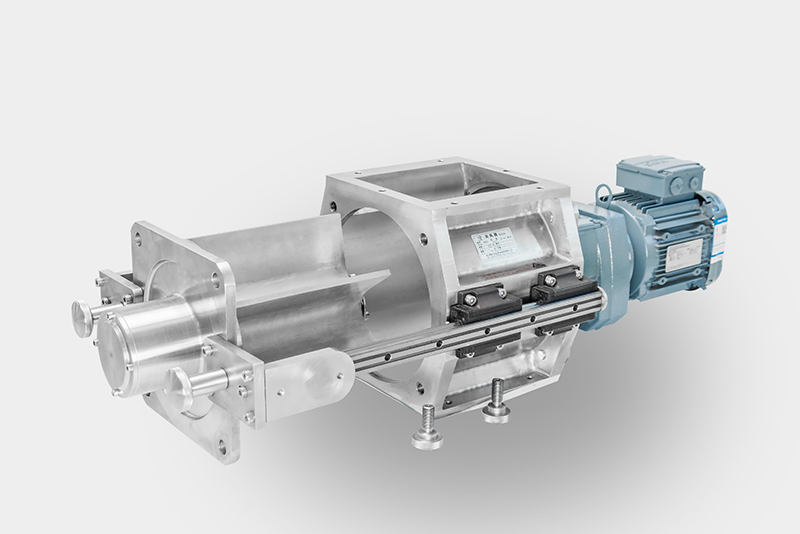

Quick Clean Valve with sanitary/hygiene design was the solution we offered in SS 304 material of construction to be mounted below the hopper.

Products in the Bakery Industries are mainly in dry powder or granular form. The main function of a rotary airlock valve is to maintain a good airlock condition, thus, isolate downstream and upstream pressure/vacuum transfer.

Quick cleaning Rotary Valve is designed for applications sensitive to contamination or process that require frequent cleaning. Its design gives easy access to rotor and internal surfaces for quick cleaning without any need to disengage the rotary valve from the system.

Quick clean rotary valves are used to reduce downtime for valve clean up, allowing removal of the rotor without removing the packing gland. The disassembly and reassembly can be done without the requirement of any tool. Further, the purging arrangement in the valve improves the life of shaft seals.

Post time: Nov-09-2021